Menu

Industry and research

Introduction

Ontario was a mineral-rich province that offered many strategic resources for military production. It also had a large population. According to the 1941 census, Ontario had 3.8 million residents, of which 62 per cent lived in urban areas. The combination of Ontario’s large population and mineral-rich land made it an ideal industrial hub for war production. By the end of the war, Ontario had lived up to its promise because it became a significant manufacturer of weapons, ammunition, equipment, vehicles and ships. But more than just a manufacturing hub, Ontario’s numerous universities and research centres made it well suited for developing military technologies.

War production

Although Ontario had virtually no munitions or manufacturing of heavy military equipment in September 1939, the province was well suited for the transition. And, unlike the First World War, the federal government anticipated a potential need to transition into war production, leading them to undertake a provincewide survey of Ontario’s industrial capacity between 1936 and 1939. This survey proved a valuable initiative that assisted in a more efficient transition during the war. The federal government also assisted industrial growth by removing profit controls on war manufacturing, and in some cases, established Crown corporations to compensate for weaknesses in the private sector. Not only did pre-existing factories prosper from rising wartime demand, but by 1945, half of the war factories operating in Ontario had not even existed six years earlier.

Policymakers and capitalists were key actors but the growth of Ontario’s industrial sector would have not been possible without the hard work of Ontario’s industrial workforce. Workers in Ontario were eager to contribute to the war industries, not only because it was patriotic, but also because they were eager to escape the destitute conditions of the Great Depression. Canada’s economy was among the hardest hit by the Great Depression. Even by the spring of 1940, there were still 600,000 Canadians on relief and unemployment was at 10 per cent. By the end of 1941, however, the labour surplus shifted into a labour shortage. The federal government responded by establishing the National Selection Service (NSS) in 1941, and the NSS’s Women’s Division in 1942, to oversee the work placements of men and women into essential industries. By 1943, over a quarter of a million women were employed in war factories, earning wages almost equivalent to men. Overall, employment in Ontario’s manufacturing sector had risen by 80 per cent since 1939, and war production employed roughly 1.1 million workers at its height. Even girls and boys were mobilized to undertake war work, ranging from model airplane construction to handling industrial machinery.

The most impressive segment of Ontario’s industrial sector was its automotive industry. In Oshawa and Windsor, there were numerous automotive plants owned by General Motors, Ford and Chrysler. Some additional facilities for motor car assembly were located in Toronto, St. Catharines and the then-separate municipality of Leaside. While Ontario’s automotive sector was impressive, it still relied on the importation of American-made engines for assembling a complete automobile. Nevertheless, the sector’s infrastructure was well-suited for producing military vehicles and its wartime record did not disappoint.

By 1945, Ontario’s automotive plants helped produce 815,729 vehicles with designated war purposes. The variety of military vehicles was impressive, encompassing 90 types based on 12 classes of chassis. Although the automotive sector was exceptional in its productivity, it should not overshadow the diversity of Ontario’s war production, which included a wide variety of equipment, ammunition, small arms and heavy weapons. It contrasted sharply with the concentration on munitions production during the First World War.

This General Motors Canada newsreel advertises the company’s military production during the Second World War.

Video courtesy of the Parkwood Estate in Oshawa. (Canadian Automotive Museum)

Another area of exceptional industrial achievement was the production of aircraft. Before the war, there were only a few small-scale aircraft manufacturers in Ontario and they did not produce fully serviceable aircraft. The industry expanded sluggishly and at great cost. By the time the Canadian Associated Aircraft Limited near Toronto produced Handley Page Hampden aircraft, it had already become obsolete. The sector improved remarkably by 1942. Large aircraft manufacturing plants were erected, including Canadian Car and Foundry and De Havilland Aircraft Company Ltd., both at Fort William, National Steel Car Company Limited in Hamilton, and Victory Aircraft Limited in Malton. These factories were crucial for Canada’s production of more than 16,000 military aircraft, including the modern fighter, “the Mosquito,” and the modern bomber, “the Lancaster.” This level of production would have not been possible without the support of more than 120,000 workers, including 30,000 women. Ontario’s aircraft industry owes another debt to American firms that supplied aircraft engines, and British engineers who provided aircraft patents.

Shipbuilding marked another industrial achievement for Ontario. Shipbuilding was concentrated on producing medium-sized vessels such as corvettes, frigates and minesweepers. Four Tribal-class destroyers were built in Halifax, but these were not completed until the end of the war. There was also the construction of small vessels such as motor launches (small military vessels for harbour defence and rescue), tugs, landing craft and motor torpedo boats. The importance of these smaller ships should not be underestimated. For instance, the Royal Canadian Navy provided the United Kingdom with a fleet of small vessels from the Great Lakes. They arrived in time to assist in the evacuation of Allied troops from Dunkirk and saved many lives.

Most ship construction was undertaken by shipyards along the St. Lawrence River and the Great Lakes. Before the war, Ontario had only two major shipyards – at Collingwood and Port Arthur (Thunder Bay). Both could produce hulls, engines and boilers. As demand for ships increased, Ontario’s dormant shipyards were reinvigorated. For instance, the small repair yard in Kingston and the nearly inoperable shipyard in Midland were outfitted for ship construction. New shipyards were also established in Hamilton and Toronto. Even shipyards at Gravenhurst, Penetanguishene, Orillia, Bracebridge and Port Carling were employed to construct motor launches. By the end of the war, Canada’s navy of 13 vessels had increased to 939 (including 373 fighting ships), making it the third-largest navy in the world. Ontario shipbuilding played a major role in this achievement.

Military research

In 1916, the National Research Council (NRC) was established to direct scientific research. The NRC continued operation during the interwar period and conducted research at its laboratory in Ottawa. In 1935, Maj.-Gen. Andrew McNaughton was appointed as the NRC President and shifted the NRC’s focus towards projects with more obvious military applications. Among those projects was research on radio, aircraft navigation, ballistics, chemical warfare and early radar. It was an important transition because the Canadian armed services had no scientific establishments, and technological advancements were needed with war looming on the horizon. Constraints on federal expenditures during the Great Depression meant that the NRC remained a relatively small organization of only 300 members, but with the onset of the Second World War, financial considerations became a secondary concern.

Between 1938 and 1945, federal expenditures on research and development rose from $4.9 million to $34.5 million. The expanded budget mirrored the strengthening ties between the NRC and the military. By March 1940, approximately 80 per cent of the NRC’s research was directly connected to wartime interests and, in 1941, the NRC became the official research centre for military services.

The breadth of NRC activity was considerable. The NRC’s laboratories increased from a single facility to 22 facilities. In addition, there were 33 Associate Research Committees, almost 100 sub-committees involved in hundreds of collaborative projects across the country. As a glimpse into the scale of this activity, the Army Technical Development Board oversaw 450 projects between 1942 and 1945 alone. Less than half were completed, and 35 were carried forward into production. In Ontario, the University of Toronto was the most heavily invested university in NRC projects, but other universities, including Queen’s and Western, had significant involvement as well. It should be emphasized that numerous NRC projects consulted American and British liaisons, making the NRC part of an international effort for scientific and engineering collaboration. Indeed, historians recognize that Canada acted as an important mediator between the British and American scientific communities.

Among the wartime achievements of Canadian researchers were their contributions to the significant development and application of radar technology. The importance of radar cannot be understated, especially as German air raids threatened the United Kingdom and German submarines threatened Allied ships. British researchers made a breakthrough at the University of Birmingham by creating the cavity magnetron, which generated a microwave signal. Thereafter, Canadian researchers went to work applying this technology in detection systems. In Ottawa, 60 scientists formed a research group devoted to radio and radar. They worked closely with British scientists and those at the University of Toronto, Western, Research Enterprises Limited (in Toronto) and McGill. Collaboration led to the design of numerous radar systems, including coastal defence radar for coastal guns, the GL Mk. IIIC system for anti-aircraft guns, long-range navigation systems, sea mine detection, airborne detection systems and the early-warning system for locating aircraft at distances of up to 160 kilometres (100 miles). University partnerships proved extremely valuable, not only for the development of radar technology but also for training operators. With these contributions, radar technology was more rapidly weaponized and used in the Allied war effort.

Another vital area of research was related to weapons. By 1943, 60 projects related to explosives were being undertaken by Canadian universities. The development of RDX or hexogen – a more stable and powerful explosive than TNT – was especially valuable. Researchers and engineers in Ontario also contributed to the development of the proximity fuse. This technology became a central component for effective anti-aircraft shells and became one of the Allies’ most tightly guarded secrets. But perhaps it was not as closely guarded as another major Allied project – the atomic bomb.

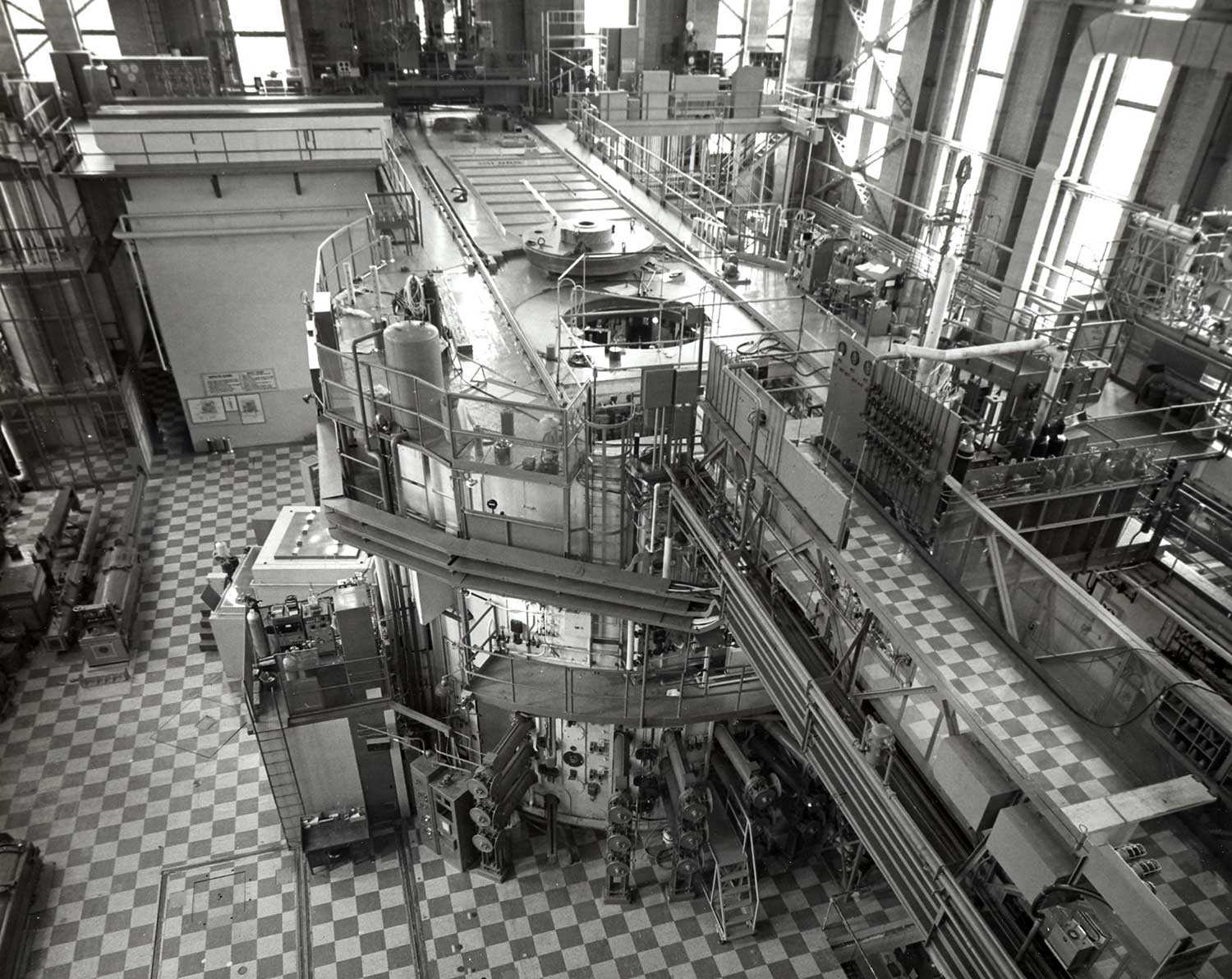

Canada was crucial for atomic research because it was a major supplier of uranium during the war. A facility in Port Hope was responsible for refining Canadian uranium. More than providing the materials, however, NRC physicists were directly involved in atomic research, including participation in the Manhattan Project. Research undertaken at a Montreal laboratory pioneered innovations related to gaseous diffusion and plutonium separation. Another research complex at Chalk River oversaw the production of fissile material used in nuclear weapons. The facility was efficient and produced plutonium three times faster than American reactors. Other devastating weapons were given considerable attention as well, including biological and chemical weapons. Allied commanders did not want to use chemical or biological warfare, but they believed its availability was a form of deterrence.

While NRC projects focused on the means to destroy, they also focused on the means to heal. Numerous innovations were made regarding antitoxins, immunization, aviation medicine, blood substitutes, shock research and nutrition. Perhaps the most reputable breakthrough was the development of penicillin. The anti-bacterial properties and minimal toxicity of penicillin had been observed by the Scottish biologist Alexander Fleming during the interwar period, but his methods required impractical quantities. The University of Toronto’s Department of Pathology and Bacteriology began research in 1941. The NRC funded the expansion of this research, especially for developing the efficient production of penicillin at the Connaught Medical Research Laboratories in Toronto. Through collaborative efforts between Canadian, British and American researchers, it became easier to produce high-potency penicillin, thereby allowing for its large-scale production. The availability of millions of doses of penicillin for the invasion of Normandy undoubtedly saved countless lives.